Tool Monitor Adaptive Control (TMAC)

Tool Monitor Adaptive Control (TMAC) system protects your CNC machine while providing valuable information about your cutting process. The system reduces the high cost of replacement tools, lost production, and rejected parts by effectively measuring tool wear in real time. It operates on the principle that the horsepower required to cut a part increases as the tool's cutting edges deteriorate.

The "Adaptive" control feature of TMAC reduces cycle time and optimizes cutting conditions to improve tool life.

Tool Monitoring

TMAC maximizes tool life by monitoring true power, not guessing with cycle count or time in cut.

- Protects your CNC machine and tools

- Determines when tools are worn or broken

- Immediate machine stop and retract when a tool breaks to minimize damage

- Remote notification of machine alarms

- Real-time data viewer

- Time stamps all monitored events

- Graphical display of cutting data for analysis

- Excellent for unattended operation

Adaptive Control

Adaptive Control regulates feedrates to maintain a constant spindle motor power for optimum cutting and reduced cycle time.

- Automatically adjusts the feedrate for each tool to maintain a constant horsepower in the cut

- Eliminates the need for manual adjustment

- Allows the tool to always cut at its optimum HP

- Adjusts for varying cutting conditions to improve tool life

For Multi-Process Machining

- Monitors multiple paths simultaneously

- Can be equipped with micro tool sensors to monitor very small tools

- Uses accelerometers to monitor machine and tool vibration

- Includes several additional applications to allow easier setup and unattended operation

- Micro sensors and accelerometers can be added as needed

- Adaptive control for each process

Additional Sensor Options

WHAT ABOUT THE DATA?

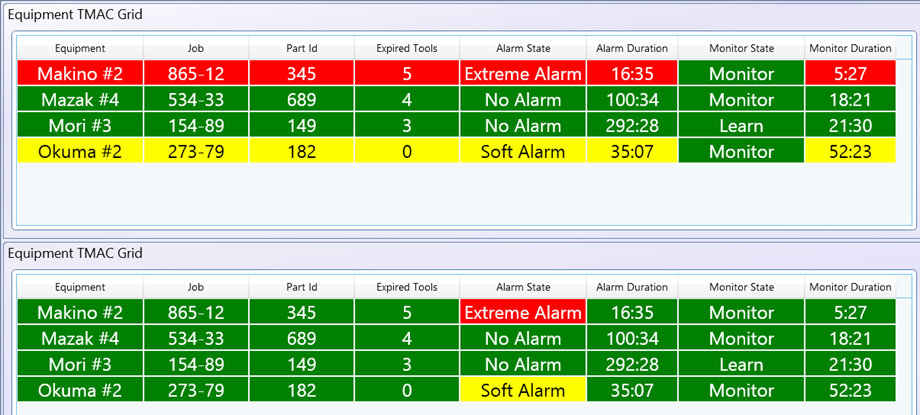

Scytec's DataXchange application integrates with TMAC so you can easily view the status of all your TMAC systems on a shop floor and analyze the data.

REAL TIME TMAC STATUS IN THE DASHBOARD

DOWNLOADS

TMAC MP Brochure

TMAC Multi Process Presentation